Table of Contents

Tires

Pneumatic

Modern tires allow cyclists to ride pavements, gravel, trails, dirt, mud, and other surfaces. Pneumatic tires, pneumatically inflated with compressed air, were invented and industrially produced before the end of the 19th century. Earlier, solid rubber was used to manufacture bicycle tires. It was better than other material. Getting a bouncy wheel that did not keep bouncing was one puzzle. Making the tire durable enough to survive contact with the road was another. Rubber proved to be elasic enough to bounce and deform and durable enough to roll for hundreds of miles.

The use of rubber for tires for automobiles and truck led to developments in material science and manufacturing, and to sophisiticated suspension systems. Suspension systems need to be damped to prevent the repetition of cycles of bouncing. Large industries rested on the discoveries that natural rubber was elastic, and could be used to manufacture devices that would contain compressed air. The development of pneumatic rubber tires for cars and trucks allowed bicycle manufacturers to acquire material and devise ways to mass produce tires. Tires have inspired the invention of tire materials, wheel rims, valves, pumps, tire levers, tools, patches, and adhesives. The newer tubeless bicycle tires have led to tire sealant, tire plugs, and tubeless repair kits.

Resources

Cyclists are interested in evaluating tires and learning which tires are efficient and economical. Tire manufacturers will happily say that they manufacture a product, and that their product is superior to other competing products. Scientific material that explains how tires work is more scarce.

Bicycle Tires and Tubes by Sheldon Brown and John Allen at Bicycle Technical Information (the Sheldon Brown site) is a well constructed page with links to terms and topics covering materials and construction. It discusses tire sizes and dimensions. BikeGremlin also explains Bicycle tyre sizing and dimension standards and other technical issues.

BTI is not a resource for information about mountain bikes. BTI published Jobst Brandt’s 1998 “A Brief History of the Mountain Bike ” which said: “The first successful high quality fat-tire bicycle was built in Marin County, California by Joe Breeze”. BTI has “suspension” in its glossary, but does not explain mountain bike suspension systems. Internet seach engines can find pages about bicycle suspension systems – for instance the Wikipedia entry Bicycle suspension but search engines do not respond fulsomely to queries about losses of energy operating bicycles on rough and irregular terrain due to vibration. There is a section on vibration in the Wikipedia entry Bicycle and motorcycle dynamics and a Wikipedia entry on vibration.

Current and historical Information on tires, rubber, and manufacturing tires available in Wikipedia, including pertinent articles explaining:

- natural rubber, and latex rubber;

- the inventor John Dunlop and the pneumatic tire;

- synthetic rubber

- butyl rubber

- vulcanizing (curing or hardening) tires;

- tire tread;

- rolling resistance.

There do not appear to be standards for how to describe the quality of tires. In a rational world, a manufacturer would have goals in developing new tires and test experimental prototypes and production models. Wikipedia has not found that many industries have adopted methods and standards. Wikipedia, as of June 2022, has pages about

- test methods,

- Quality Management systems, and

- consumer-oriented product testing.

Engineer and blogger Tom Anhalt wrote about tires, tube and pressure at the online triathlon magazine Slowtwitch.com, some listed here, and wrote articles on his own Blogspot blog Blather ’bout Bikes:

- July 2007 Tires and wheels for timed cycling events;

- August 2009 What’s in a Tire;

- September 2009 What’s in a Tube

Derek Lakin writes at site called TreadBikely. It seems to be a commercial site. The site has illustrated articles that discuss tire manufacturing:

- How Bike Tires Work: Your Quick-Reference Visual Guide;

- What Are Bicycle Tires Made Of? A Step-by-Step Exploration of the Manufacturing Process.

Tires

Tire beads

A bicycle tire is a strip of durable and stretchy materials laid out in a circle, with edges pulled up to shape the tire in a U-shape. Most tires have beads, a structural part that is durable but not stretchy:

Conventional tires used on 99% of all bicycles are “clincher”type … They consist of an outer tire with a U-shaped cross section, and a separate inner tube. The edges of the tire hook over the edges of the rim, and air pressure holds everything in place.

….

The “bead” is the edge of the tire. On most tires, the beads consist of hoops of strong steel cable. The beads hold the tire onto the rim, and are, in a sense, the “backbones” of a tire. While most beads are steel, some tires use Kevlar ® cord instead.

Sheldon Brown, John Allen, Bicycle Technical Information, Bicycle Tires and Tubes

Wire beads are less common than they were in the 1980s. Modern bicycle tire manufacturers use synthetic compounds to manufacture tire beads. Synthetic aromatic polyamids (Aramid) are popular. The rim of a clincher wheel is machined to turn inward to hold the bead in a “bead” hook. Clincher tires use an inner tube, which is airtight and inflated. The butyl rubber inner tube is the ordinary tube; latex tubes for clincher tires are available.

Tubeless tires are clincher tires without inner tubes. They have to be airtight to be inflated without inner tubes. The wheel rim is sealed with a airtight rim tape. The valve is sealed to the rim (and not to inner tube, passed through and opening. A tubeless ready tire is a clincher tire with an inner tube. A tubeless ready wheel rim may have tubeless rim tape, but a tubeless ready system has an inflatable inner tube – the valve is attached to the tube. Tires have been securely clinched to the wheel and sealed airtight by matching the bead with a bead hook structure or bead channel in the wheel rim.

Tubeless tires need liquid sealant in the tire to seal the tire to the rim. The liquid sealant is also supposed to block small leaks and punctures, as well as sealing the bead. A rider can carry tools to plug a small puncture and reinflate it if the sealant has remained in the tire and still functions. As of 2022, manufacturers of wheel rims are building and promoting rims without bead hooks for tubeless tires. There are cost savings in manufacturing wheel rims, and time and cost savings in changing tires, at the risk of tires coming off the rim.

A “tubular” tire, not to be confused with a clincher, also uses an inner tube. Tubular tires are explained at BTI. Tubulars are uncommon and mainly found on racing bikes.

Casing, Sidewalls & Tread

The body of the tire, technically called the carcass, commonly referred to as the casing, is made of “threads”, coated with plastic and rubber compounds:

Cloth fabric is woven between the two beads to form the body or “carcass” of the tire. This is the heart of the tire, the part that determines its shape. The vast majority of tires use nylon cord, though some use other polyamides. … The fabric threads don’t interweave with crossing threads as with normal cloth, but are arranged in layers or “plies” of parallel threads. Each layer runs perpendicular to the next layer(s).

Some tires use thick thread, some use thin thread for the fabric. With thin thread, there are more threads per inch (“TPI”) and this number is often considered an important indication of tire performance. The higher the TPI number, the thinner and more flexible the tire fabric is. Thin-wall (high TPI) tires tend to be lighter and have lower rolling resistance, but they’re more easily damaged by road hazards.

Bicycle tires have the threads of the fabric running diagonally, (“bias”) from bead to bead. Modern car tires have the main threads running straight over from one bead to the other, known as “radial” construction. Radial tires will also have a “belt” of plies running all the way around the circumference of the tire, crossing the radial plies.

Sheldon Brown, John Allen, Bicycle Technical Information, Bicycle Tires and Tubes

In automobile and truck tires, the threads are called cords and may be made of metal. The term cords is also used to refer to bicycle tire threads. Few modern bicycle tire threads are not made of natural plant fibers (e.g. flax, hemp, cotton). Most are filaments of petroleum synthetic (i.e. plastic), often nylon, spun into threads. The threads are not woven into a cloth or fabric. Thread count is a (vague) measure of the texture of woven fabrics – particularly cotton bed sheets. Thread count is not generally a selling point for modern bicycle tires, except that high thread count was used by some manufacturers to mean that that a casing is strong and “supple”.

The threads cross each other in a grid, and are coated in an elastomer – a plastic compound. Some machines produce ribbons of the specified width; some machines produce sheets that are cut to ribbons of the required width. The ribbons are folded over the beads and welded. The threads reach from bead to bead, on the bias (diagonally). Layers of rubber or synthetic rubber compound are applied to the ribbon to form the sidewalls and the tread. The tires are pressed into moulds, shaped, and laminated. In some tires groups of threads (belts), are laid down with the bands crossing each other.

The tread is the part of the tire that contacts the road:

… This area usually has thicker rubber than the “sidewalls” of the tire, mainly for wear resistance. Most tires have some sort of 3-dimensional pattern molded into the tread, which may or may not enhance traction.

Manufacturers mix different additives with the rubber to achieve desired traction/wear characteristics. Generally, a softer formulation will give better traction, but at the expense of more rapid wear. Rubber is normally a sort of tan color, but most tires are black. This is the result of adding carbon black to the mix. Carbon black considerably improves the durability and traction of the rubber in the tread area.

Sheldon Brown, John Allen, Bicycle Technical Information, Bicycle Tires and Tubes

A tread pattern of grooves in a thicker tread is common for automobiles. It was common for bicycle tires through the greater part of the 20th century, except for some special purpose tires. Tread patterns on bicycles do not displace water. Hydroplaning on a bicycle on concrete or asphalt is not a risk . BTI addressed this in a general article and in a 1997 article by Jobst Brandt, “Tires with Smooth Tread. A writer at CyclingTips addressed treads in 2014 in Rubber side down: the function of road tyre tread patterns:

A road tyre is already very effective at displacing the water thanks to its round profile so Jobst Brandt has argued that a patterned tread is unnecessary. A broader survey of current thinking amongst tyre manufacturers supports this view, though some see room for marginal gains through a tread-pattern design.

Slicks or near slicks have become a popular choices for “road” bikes. Some favour a file tread pattern (thin shallow closely spaced ribs at an angle to the path of travel; like the cutting edge of a file – the tool). Jan Heine, the editor of Bicycle Quarterly, and principal of René Herse Cycles addressed this:

… we are examining myths in cycling – things that we (and most others) used to believe, but which we have found to be not true. Today, let’s look at tire tread: Tread patterns matter – they can make a difference – even on the road. “Bicycles don’t hydroplane,” declared some experts many years ago. “Hence, tire tread patterns don’t matter on the road.” The first part is true – even wide bicycle tires are too narrow to lose traction due to hydroplaning – but tire tread doesn’t only serve to evacuate water from the tire/road interface.

In fact, the tread of bicycle tires has other purposes. I once cycled on the polished stone that surrounded a college library, and I was surprised by the lack of grip: I crashed. Even though I was unhurt, I learned the hard way that the coefficient of friction between our tires and the rocks that make up the road surface isn’t very high. Yet we don’t crash on roads made from the same rocks, but in the form of rougher aggregate in pavement. What happens is that tire and road interlock to create grip.

If our grip came only from pure friction, the size of the contact patch wouldn’t matter. Physics tells us that if you double a tire’s width, it will be pushed into the road surface with half as much force – the two cancel each other. Yet race cars run ultra-wide tires because they provide more grip. What is going on?

Tires interlock with the road surface. Imagine each little surface irregularity like a spike that pushes into the tire. The wider the tire, the more surface irregularities it touches; hence it has more grip. A softer tire also has more grip because the road surfaces pushes deeper into the tire. That is why the tires of race cars use very soft rubber, and why wider bicycle tires at lower pressures offer more grip than narrow ‘racing’ rubber at higher pressures.

There is another way to increase the interlocking between tire and road: provide edges on the tire that ‘hook up’ with the road surface irregularities. Each edge provides a point where a road irregularity can hook up. The more edges you have, the better the tire hooks up.

Jan Heine, February 22, 2018 (updated 2020) René Herse Cycle Journal, Myth Debunked: Tread Patterns Matter, even on the Road

Contact Patch, Deflection, Tire Drop, Rolling Resistance

The weight of the bicycle rests on the contact patches of the tires, the area where each tire deforms from the circular shape of the tire in cross section to the (flat) shape of the surface as the bike rolls forward.

… the role of air pressure in the tire is to hold the fabric under tension — in all but one place, the contact patch with the road surface.

Air pressure can’t add tension at the contact patch, because the contact patch is flattened against the road. Air pressure can only push directly outward, and so here, it pushes directly downward. The downward force of the air must equal the weight load, and so the area of the contact patch approximately equals the weight load divided by the air pressure. (Edge effects and skewing of the weave of the fabric may result in some difference.) For example, if the air pressure is 50 PSI and the load is 100 pounds, the contact patch will be about two square inches.

The threads of the tire fabric can transmit loads only lengthwise and in tension. How then, do they transfer the load from the contact patch to the rim?

Because the contact patch is flat against the road, the curvature of the sidewalls next to it is increased, decreasing their tension, and the angle at which they approach the contact patch becomes shallower. These effects produce the bulge seen at the bottom of a tire under load and transfer the load from the contact patch to the tire sidewalls. The threads of the fabric are pulling downward less and outward more. The load is similarly transferred from the sidewalls to the rim. The sideways forces at the right and left side of the tire are equal and opposite, and cancel out.

Sheldon Brown, John Allen, Bicycle Technical Information, Bicycle Tires and Tubes (see How a Tire Supports its Load)

The rubber at the contact patch bends and rebounds like a spring. The rubber is under tension. The air everywhere in the tire is under pressure but the the tire bulges at the contact patch. The tension of the tire supports the bike.

Because the contact patch is flat against the road, the curvature of the sidewalls next to it is increased, decreasing their tension, and the angle at which they approach the contact patch becomes shallower. These effects produce the bulge seen at the bottom of a tire under load and transfer the load from the contact patch to the tire sidewalls. The threads of the fabric are pulling downward less and outward more. The load is similarly transferred from the sidewalls to the rim. The sideways forces at the right and left side of the tire are equal and opposite, and cancel out.

….

A tire, then, supports its load by reduction of downward pull, very much the same way that spoking of the wheel supports its load. The tension-spoked wheel and the pneumatic tire are two examples of what are called preloaded tensile structures, brilliant, counterintuitive designs working together remarkably to support as much as 100 times their own weight.

Brown and Allen, Bicycle Technical Information, “How a Tire Supports its Load“

The rolling resistance of a tire is an example of elastic hysteresis. The deformity also causes the steering tire to experience pneumatic trail.

Frank Berto (deceased December 2019) was the technical editor of Bicycling magazine, before it became a travel and lifestyle publication. He wrote a book on derailleurs, The Dancing Chain – the 2016 5th edition is still on the market. Frank Berto wrote notable articles on “tire drop” – the change in the height of tire when it bulges under load. Some appeared in Bicycling and other print publication, but were not digitized. He rewrote and updated an article called All About Tire Inflation in 2006. Berto wrote or contributed to an article for Jan Heine’s Bicycles Quarterly published in Issue 19 (V. 5, No. 3, Spring 2007). Steve Vigneau has a pdf copy of “All about Tire Inflation” at his site: https://nuxx.net/files/bicycle/various/Frank_Berto-All_About_Tire_Inflation.pdf. Perhaps other copies and other articles can be located on the Web. Frank Berto explained why road bike tires should be inflated to endure tires stayed on the rim under the forces of cornering, and to avoid “pinching” and deflating an inner tube. For road bikes on pavement, he suggested the pressure should be high enough that tire drop was about 15%. He thought that road riders were overinflating their tires. He thought that mountain bike rides should ride softer, but needed guidance to know the minimum pressure to avoid damage to tires and rims.

Frank Berto largely agreed that road bike tire pressures could be lower than the manufacturers’ marked safety warning. He thought that bike tires need pressure to support the bike and rider and to handle properly. He suggested that the pressure should be enough to keep tire drop around 15% for the bike, rider and load. Tire drop is hard to measure. Like rolling resistance and durability, it is dependent on pressure and the thickness and composition of the tire casing

The deformity causes rolling resistance:

“Rolling resistance” is the mechanical friction generated as the tire rolls. As a segment of the tire tread rolls into contact with the road, it deforms from its normal curved shape into a flat shape against the road, then back to the curve as the tire rolls onward. The deformation of the rubber in this process is what causes the friction. A bias-ply tire has some additional friction because of the “Chinese finger puzzle” effect of the bias plies. The edges of the contact patch scrub against the road as a segment of the tread becomes shorter and wider where it flattens out, then longer and narrower as it becomes round again.

Brown and Allen, Bicycle Technical Information, Bicycle Tires and Tubes: Rolling Resistance

Wider, Softer, Supple

Road Bikes

Manufacturers and consumers used wider tires for some bikes and some kinds of riding for a long time. Mountain bikes had and have wider tires. Gravel bikes have wider tires. Cyclo-cross bikes have wider tires than road bikes. Wider tires hold larger volumes of air at lower pressure than narrower tires:

Tire width and pressure are inextricably linked. It is a serious mistake to consider one independently of the other. Generally, wider tires call for lower pressures, narrower tires call for higher pressures.

Consider, for example, a tire one inch across, at a pressure of 100 PSI (pounds per square inch). Air is pushing down against the bottom half of the tyre cross-section with a force of 100 pounds per inch of length. Each sidewall of the tire bears half that load, and so each inch of length of tire sidewall will be under a tension of 50 pounds. Now let’s consider a tire twice as wide, two inches across, at the same 100 PSI. Each inch of sidewall will be under a tension of 100 pounds. So, a wider a tire would ride harder, and need stronger fabric, if inflated to the same pressure,

The part of the tire that is actually touching the ground at any moment is called the “contact patch.” Generally, the area of the contact patch will be directly proportional to the weight load on the tire, and inversely proportional to the inflation pressure. For instance, if the rear tire of a bike is supporting a load of 100 pounds, and the tire is inflated to 100 PSI (pounds per square inch) the contact area of the tire will be roughly one square inch. If the pressure is reduced to 50 PSI, the tire will squish out until the contact patch has become 2 square inches (or until the rim bottoms out against the tire.)

A common debate among cyclists centers on the issue of whether a wider tire has more or less rolling resistance at the same pressure. The constant pressure is proposed because it appears more scientific to eliminate this as a variable, but this is not realistic in practice. The short answer to this question is that, yes, a wider tire of similar construction will have lower rolling resistance than a narrower one at the same pressure. This fact is, however, of no practical value. If you are comparing two tires of similar construction, with the same load, and the same pressure, either the wider tire is overinflated, or the narrower tire is underinflated!

A tire is supposed to deflect a bit under load. This deflection [is] the whole purpose of pneumatic tires. When you sit on your bike, your tires should visibly bulge out at least a bit under your weight. If they don’t, they’re overinflated.

Brown and Allen, Bicycle Technical Information, Bicycle Tires and Tubes: Width

Stiffness can come from thicker casing and rubber. Tire designers can make tires “supple” by making them with thinner casings and thinner rubber layers on the sidewalls and treads. A supple tire stetches and rebounds rapidly with little loss of energy. It rolls with little rolling resistance, and suspends the bike.

Supple tires have drawbacks:

There are four ways to reduce [rolling resistance], each subject to trade-offs:

[1.] The thinner and softer the rubber/fabric of the tire are, the more flexible they become. The trade-off with this is that the thinner the tire gets, the more fragile it is, and the sooner it will wear out.

….

Brown and Allen, Bicycle Technical Information, Bicycle Tires and Tubes: Rolling Resistance

If the casing and tread are thin, the tire is fragile. The entire contact line of a supple slick tire is exposed to contact with and penetration by small sharp debris. The tread and sidewalls can be gashed by impacts with sharp or pointed edges including broken glass, metal objects etc. on paved roads., and rocks, thorns on gravel and trails.

A patterned tread of hard rubber provided reasonable protection against punctures from small debris, although a pattern leaves an area of the tread with less rubber. The industry addesses puncture resistance with thicker or stronger tire casings and with protection belts. See Cycling Weekly’s Best puncture-proof tyres for cycling 2022.

Knobs & Cleats

Bike, wheel and tire manufacturers designed mountain bikes and gravel bikes with wider tires than road (and cyclo-cross) tires. Tires, with raised tread features – i.e, knobs, ridges or cleats were and are common on mountain bikes. Hybrid mountain bike tires are wider than “traditional” narrow road bike tires but narrower than mountain bike tires. Hybrid mountain bike tires, commuter bike tires and utility bike tires tend to have flat, patterned treads. Generally, gravel tires have knobs.

According to Jan Heine of René Herse Cycles, knobs and other tread patterns do not increase traction on loose aggregate surface materials (gravel). The tires ride on the aggregate material on the top.. The top aggregates slide or tumble on the lower loose material. Knobs do not increase grip on such a surface. Knobs can grip irregular firm surfaces and surfaces covered by thin layers of loose materials.

Some knobby tires can “squirm”:

Knobby treads actually give worse traction on hard surfaces! This is because the knobs can bend under side loads, while a smooth tread cannot. The bending of knobs can cause discontinuities in handling: the tire grips OK for mild cornering, but as cornering force exceeds some critical value, the knobs start to bend and the traction suddenly goes to Hell in a handbasket.

Brown and Allen, Bicycle Technical Information, Bicycle Tires and Tubes: Squirm

It depends on the size and shape of the knobs, the tread material, and the way the tire deforms and contacts the road. The tire streches and deforms around around knobs when the knobs are under the contact patch.

Thick knobs are less vulnerable to puncture than the thinner parts of the tread when the knobs are in the contact patch. The risk of puncture depends on the shape and size of the debris, the angle of impact, speed, and weight. I can’t find any discussion of the role of knobs in protecting the tire from puncture by small debris.

The knobby mountain bike tires made in the 1980s and ’90s were noisy. Tires with knobby tread were also generally thicker and stiffer. Knobby treaded tires were slower because the tires were stiff and slow. I switched from knobby tires to a patterned tread tires on my Giant hardtail mountain bike, and rode patterned tread tires on my hybrids and my old road bike for years. I was quieter and I thought I was faster. I don’t really know.

Manufacturers have modified tread patterns with knobs and cleats to reduce noise. Modern raised tread patterns are more likely to hum rather than buzz or roar, but can still be noisy.

Valves, Chucks, Gauges

The Schader valve used on automobile tires was used on bicycles in North America. Presta valves were once found mainly on the narrow tires and tubes of road bikes. Presta valves have become common on gravel bikes. mountain bikes and hybrid bikes. Bicycle Technical Information lists Schrader, Presta and Dunlop and illustrates these valves. Wikipedia’s valve stem entry has a 4th type.

A valve stem is a self-contained valve. Cyclists refer to the exterior shell, which is often threaded, as the stem. Some small bike pumps can be attached to the stem. Most pumps attach to the stem with a hose fiting on the pump hose called a chuck.

The Schrader valve allowed cyclists to use air pumps at automobile service stations. The pumps had chucks to fit on Schrader valves, and worked on Presta valves if the user had an adapter. These pumps were useful for cyclists if a service station was near (before service stations began to put coin meters on air pumps) if the user could limit or control the volume and pressure. Some industrial pumps could blow out a bike tire, delivering large volumes at high pressure.

In the 1950s and 60s young cyclists learned to test pressure by grasping the wheel rim and pressing the tread to see if the tire would deform under that pressure. It was not a measurement and it depended on strength and effort. Modern riders have access to analog and digital gauges to test pressure, cycling computers to record speed, location and elevation and power meters.

Pressure – Warnings, Manufacturer Recommendations

Many riders expect the manufacturer to specificy an optimal recommended operating pressure. The value stamped or marked by the manufacturer on the sidewall is not the an optimal value or the optimal value:

Most tires have a “maximum” pressure, or a recommended pressure range marked on the side of the tire. These pressure ratings are established by the tire manufacturers after consultation with the legal and marketing departments. The lawyers want the number kept conservatively low, in case the tire gets mounted on a defective or otherwise loose-fitting rim. They commonly shoot for half of the real blow-off pressure. The marketing department wants the number high, because many tire purchasers make the (unreliable) assumption that the higher the pressure rating, the better the quality of the tire. Newbies often take these arbitrary ratings as if they had some scientific basis. While you’ll rarely get in trouble with this rote approach, you will usually not be getting the best possible performance. … Optimal pressure for any given tire will depend on the load it is being asked to support. Thus, a heavier rider needs a higher pressure than a lighter rider, for identical tires.

….

Rough surfaces generally call for a reduction in pressure to improve ride comfort and traction, but there is a risk of pinch flats if you go too far. Even at the lower appropriate pressure, wider tires, because they also are deeper, are more immune to pinch flats.

Brown and Allen, Bicycle Technical Information, “Pressure & Pressure Recommendations“

Industry Testing

Testing of tires for automobiles and aircraft (landing gear) for safety was established by governments, regulatory agencies and regulatory bodies. The performance of materials and components in the various situations became a testing point, and testing would have been necessary to sell those products.

Bicycles have been athletic, recreational and entertainment products, and a means of transportation, and even toys. Tire testing, unless required by consumer protection law or the rules of competition, was unusual. The test data for bicycle tires, if any, may be found in the papers of the inventors and manufacturers.

Josh Poertner, the principal of Silca Velo suggested (to Tom Anhalt in an interview (link below), that manufacturers of bicyle tires had no data about tire operation or performance because they were not testing, and that no one knew how to test bicycle tire performance until the early decades of the 21st century. Poertner said that manufacturers relied on their own reputations and industry practice when they made claims that tires were “fast”, efficient, grippy, puncture-resistant, comfortable etc. In a few of the earliest Silca Velo podcasts Josh Poertner discussed tires and inteviewed engineers who had started bicycle tire performance testing:

- Hysteresis

- Podcast November 4, 2019- Hysteresis in Marginal Gains;

- YouTube Video (February 26, 2020);

- November 19, 2019, Podcast – A Conversation with Robert Chung;

- July 9, 2020 Podcast – Tire Pressure Pioneer: Tom Anhalt.

Cyclists started to demand, unsuccessfully, that when manufacturers claim that competive road casing tires are efficient or fast, they should disclose data. Manufacturers can feasibly test protypes and production samples on testing devices that put pressure on tires as tires are rotated against rollers and drums. Manufacturers prefer to rely on brand reputation and price to persuade riders that a tire is fast, light or high quality.

It is not likely that manufacturers will ever voluntarily disclose research on materials and products under development.

Consumer-led testing

For several decades, from the 1960s, riders, mechanics, bike shops and tire manufacturers shared a common belief and maintained that road bike tires should be narrow and inflated to high pressures. Several sectors of the cycling industry were vested in narrow tires by the 1990s. Road bike frame and fork designs accomodated narrow tires. Wheel manufacturers manufactured wheel rims for narrow tires. Tire manufacturers made narrow tires and tubes.

Cycling magazines seldom pay journalists to test products or challenge the practices of manufacturers who pay magazines to advertise products and publicize cycling. There was some industry reseach on rolling resistance in bicycle tires, but the methods and results are obscure. In an article on the triathlon site Slowtwitch.com:

I’ve heard, though I haven’t seen, reports of rolling resistance studies Continental performed that included an analysis of tire width. … it seems intuitive to me, that there is not much if any measurable difference in the rolling resistance of a 20mm tire versus a 24mm tire, all other things equal. Thinner tires require more attention, though, in that they’re more susceptible to increased rolling resistance if they’re not inflated to a sufficient pressure.

….

After you’ve satisfied yourself (or if you’re willing to take my word for it) that a 23mm or 24mm tire will roll as efficiently as a 9mm or 20mm tire, you can move to the next two issues, which are aerodynamics and resistance to flats.

Dan Empfield, Slowtwitch.com, September 2002, Rolling Resistance

Cycling computers and tire pressure gauges allow riders to check their real speed, tire pressure and other parameters. This allowed riders to compare tires and tire pressures.

Independent researchers including Robert Chung, Al Morrison, Tom Anhalt and Jan Heine started research into road bike tires at or after the end of the 20th century. They recorded data with gauges, cycling computers and power meters available to them. They communicated with each other, sometimes, on Usenet or in other internet services, or by telephone.

Tom Anhalt’s equations to convert Crr (Coefficient of rolling resistance) on rollers to flat surface were written in 2006 (published in 2013 on his blog Blather ’bout Bikes) Tire Crr testing on Rollers – The Math. His charts comparing narrow triathlon road racing tires were published in 2013 on his blog Blather ’bout Bikes, Tire Crr Testing on Rollers – The Chart … and a “how to”. Tom Anhalt’s 2009 article on inner tubes formulated the theory of the breakpoint, at which increasing tire pressure increases rolling resistance:

When thinking about tire pressure and what is “fast”, it helps to think of it in terms of a “resistance to forward motion” rather than just thinking about the rolling resistance of the tire itself. As we’ve seen above, increasing pressure inside the tire decreases the rolling resistance of the tire itself, and this fact has been observed in tests of rolling resistance vs. tire pressure on smooth rollers. With increasing pressure, the rolling resistance drops at a decreasing rate until at very high pressures it’s basically a flat line. So, does that mean that increasing pressure in a tire lowers the rolling resistance of the tire on a rougher surface as well? The answer is: “Yes…but..” The rolling resistance of the tire continues to decrease with increasing pressure on rough surfaces as well, BUT at some point the increasing pressure stiffens the “air spring” so much that the increase in transmitted energy loss overwhelms the decreasing rolling resistance of the tire, with the result being that the actual ” resistance to forward motion” starts increasing.

Tom Anhalt, Slowtwitch.com. September 21, 2009, What’s in a TubeThe net result is that above a certain pressure (what I like to call the “breakpoint pressure”) higher inflation pressures make a rider slower for a given power input to the pedals. Adjacent is a simplified schematic representation of this effect. Very little data is commonly available that shows this effect. Mainly out of curiosity about whether or not this effect was measurable, and to what the magnitude of the effect was, this author undertook an experiment “on the road” armed with a PowerTap power meter and a method for determining the Crr (coefficient of rolling resistance – actually, in this case the “resistance to forward motion” proportional to velocity) illustrated here.

Robert Chung developed a power equation that considered Cda (drag area) as well as Crr. He wrote a paper “estimating CdA with a power meter” which has been distributed on the internet. Tom Anhalt discussed the March 2012 version of the paper in his Blather ’bout Bikes post August 4, 2013 “Aero Field Testing using the “Chung Method” – How sensitive can it be?“.

Lower pressure was an innovation when applied to road bicycle tires. Some professional road racing teams or their consultants began to experiment. Some experimenters tried to protect their data and insights to maintain advantages for racing teams, consultants, and tire manufacturers. Academics publish. Manufacturers and consultants hoard trade secrets.

Josh Poertner, before acquiring the Italian Silca Velo brand, had worked on wheels and tires as a manager in Zipp’s Speed Weaponry division, advising professional road racing teams. He was familiar with the literature, and was involved in testing. Josh Poertner/Silca Velo started to podcast or make videos in 2019. Josh Poertner sometimes suggests that the modern engineering of Anhalt has superceded the views of Frank Berto. Anhalt relied on some of Berto’s work in a post on gravel tires February 16, 2020 and his graphs on rolling resistance and pressure. The reasoning and the math is complicated. It seems that Anhalt did not overthrow Berto’s work.

Bicycle Quarterly

Bicycle Quarterly (“BQ”), is a printed publication founded by Jan Heine, the principal of Compass Cycling and René Herse Cycle of Seattle, Washington, USA. BQ was first published in 2002 as a publication about “vintage” bikes. Jan Heine favours drop bar bikes without mechanical/hyrdraulic suspensions: road bikes, endurance road bikes, and “all-road” bikes. His favoured off-road forms of riding include cyclo-cross. He rode Unbound Gravel in Kansas in 2022 on a vintage design René Herse 12 speed (2 x 6) all-road bike. He reviews bikes built by custom builders – frequently bikes built with steel frames. BQ has discussed the uses of bicycles on gravel roads, and self-supported distance riding (randonneuring). René Herse Cycles has a YouTube channel. Some of the videos are about rides in the Cascades and other parts of the US Northwest. Some illustrate bike design, handling, and maintenance:

Most of Jan Heine’s books were independently published by Bicycle Quarterly Publications and sold by René Herse Cycles, and by Amazon:

- The Competition Bicycle (2008, reprinted 2012),

- The Golden Age of Handbuilt Bicycles: Craftsmanship, Elegance, and Function (2009),

- René Herse: The Bikes • The Builder • The Riders (2012),

- The All-Road Bike Revolution (2020).

Several of Jan Heine’s books explore history and document the quality of 20th century bicycles. The 2020 book is a short manual for purchasers and riders, and discusses features of modern bikes. Jan Heine frequently observes that modern bikes originated in bicycle designs in the early and middle parts of the 20th century. He respects innovation, but has raised questions about innovations that fail to improve the owner/rider’s experience. He points out that a steel bike from a home builder or small manufacturer can be a better bike, and less expensive than most bikes produced by modern factories.

BQ discussed tire pressure, tire testing and tire design many times. Jan Heine and other riders and writers associated with BQ began testing and writing about rolling resistance and tire tests in BQ issue 17 (aka Volume 5, No. 1, Autumn 2006). Heine respects Frank Berto’s efforts to measure tire drop – he relied on it in developing the René Herse online pressure calculator tool, which became active in the spring of 2022, and cites Berto in journal entries such as “Tire Pressure Take Home” (March 2016).

BQ writers criticized the lack of testing by tire manufacturers, and the use of machines that tested tires on steel rollers or drums. They preferred to test tires by comparing performance on the same surface, without pedalling, by letting bikes roll down measured distances, downhill under low wind conditions – the “roll-down” test. It is a low-tech process that requires time, and measurements of distance, time, and speed. Jan Heine designed tires, manufactured (according to some sources by Panaracer) for Compass and René Herse in Japan, and brought the tires to market. He can be seen as :

- a fan of vintage bikes and

- promoting his brand of supple tires, and

- questioning some of the practices of bike and tire manufacturers.

Jan Heine maintains that hard narrow tires cause the bike to vibrate, even on smooth pavement, which riders perceive as an indication the bike is fast. He summarizes his reseach as supporting the view that an overinflated (hard) tire transmits vibration which slows a rider down – a hard tire is not an effective shock absorber. Jan Heine expressed his views to the readers of the Adventure Cyclist magazine of the Adventure Cycling Association in March 2009 in the article “PSI Rx“. The article discussed the way tires lose energy the rider put out to get the bike rolling forward:

Suspension losses – a bike that vibrates and bounces from one bump to the next is lifted up time and again. Lifting the bike requires energy. Part of this energy is absorbed inthe rider’s body and, on a touring bike, by the luggage. The rest is returned as the bike rolls off the bump. When you accidentally ride into the rumble stripsthat separate many U.S. highways from the shoulder … you also slow down immediately as energy is absorbed in your body. By smoothing out the bumps, pneumatic tires save energy.

Deformation losses – the downside of a soft and squishy tire is the deformation of the tire as the wheel rotates. Most of the energy necessary to bend the tire casing is returned as it springs back into shape at the rear of the contact patch, but some of it is lost to friction within the tire and is no longer available to drive the bicycle forward.

For the best performance and comfort, you need a tire that is neither too hard nor too soft. Instead of inflating your tires to the maximum pressure, run them at the optimal pressure, where they deflect enough to keep the bike from vibrating too much yet are not so soft that they slow down due to excessive deformation losses.

Tire drop measures how much the tire deflects under the load of rider and luggage (Figure 1). For example, if your tire is 30 mm tall without a load and 27 mm tall once you sit on the bike, your tire drop is 3 mm or 10 percent.

….

Properly inflated, wider tires provide much more comfort. When you hit a bump and your tire drop increases from 15 to 18 percent, the 23-mm tire will give you only 0.69 mm suspension, whereas the 37-mm tire deflects 1.11 mm. The added suspension of the wider tire makes it faster and more comfortable on rough roads.

But aren’t narrower tires faster? Not really. The key to a fast tire is a supple thin casing that requires less energy to deform than a sturdier thicker casing. For a variety of reasons, many wide tires use heavy-duty casings, which are indeed slow. Wide tires with high-performance casings can be very fast. In Bicycle Quarterly’s tests, the five fastest tires ranged in width from 24 to 37mm. … thin supple casing is faster because it absorbs less energy as it deforms.Thus, it will deform more for a given bump, making it more comfortable than a sturdier tire with a thicker casing (for the same tire width and pressure). The downside of a thin supple casing is reduced resistance to punctures.

Jan Heine, March 2009, Adventure Cyclist, PSI Rx

Jan Heine’s point is that a supple tire deforms and recovers faster, and absorbs road vibration that a stiff tire will not. Jan Heine acknowledges that the thin supple casing has disadvantages and risks, including reduced resistance to punctures. In the printed BQ articles about his attempts in 2021 to record the Fastest Known Time on the Oregon Outback route, he discusses the risks of gashing supple tires on sharp rocks on gravel surfaces.

Jan Heine and Josh Poertner were guests on CyclingTips Weekly Podcast Episode 9, August 21, 2016 “Rethinking road bike tire sizes and pressures“. Elden Nelson, the (former) blogger at Fat Cyclist was the podcast host. (Elden Nelson and Michal Hottner co-host a podcast about the Leadville Colorado mountain bike race, and the Silca Velo Marginal Gains podcast. He stopped blogging in 2022). James Huang, a CyclingTips technical writer, was a guest or co-host. It may be necessary to play the mp3 version – the 2016 episode is not available in the podcast search function in several podcatcher apps. It is over an hour long. Jan Heine and Josh Poertner agreed that lower pressures were faster. The discussion was summarized in an article in/on CyclingTips in 2017 “What is the optimal tyre pressure?“

The amount of energy that is wasted due to suspension losses increases significantly as the surface of the road gets rougher. Jan Heine measured huge losses when riding the rumble strips that border some roads while Josh Poertner found that even a small amount of over-inflation (10psi) could produce an obvious penalty.

….

Much of the data favours wide (25-28c), supple tyres at lower pressures (60-80psi/4-5.5bar), but every rider should feel free to experiment with tyre size and pressure until they are pleased with the performance of the bike.

They agreed that many riders would be better off with wider, softer and more supple tires, and that the optimal tire pressure is usually below the manufacturer’s safety warning. Each had reasons, and relied on particular data points. Poertner cited “supple” practices of professional road racing teams such as the use of latex inner tubes (as opposed to the more common butyl rubber tubes) and the use of thin casing supple tires in races. Poertner agreed that that overpressure beyond the breakpoint (see Tom Anhalt, above) can produce a penalty. They had some differences, but they did not discuss or debate them. The article in/on CyclingTips is imprecise on some points. As the breakpoint is dependent on weight and sensitive to surface, a rider may have to monitor pressure, use data based calculator programs, and test. Rolling resistance cannot be stated for a tire, without knowing other parameters.

The Consultant’s View

Josh Poertner is an engineer and entrepeneur:

- He views reducing tire pressure as a way of reducing rolling resistance as a marginal gain for competitive riders;

- He favours the idea that new ideas, methods and products are generally better;

- He is aware of the costs and constraints affecting the way tires are made – the cost of material, the costs of machines, transportation, energy and labour;

- He is aware of the way engineers in the automobile-related industries have addressed the constraints;

- He is responsive to the financial constraints of industry.

Like the Ferengi on Star Trek, manufacturers focused on the acquisition of profit as the highest goal can resist making performance the highest standard – it a customer wants high performance, like a professional cycling team manager, the customer needs lots of money.

By 2016, according to Josh Poertner, several road racing teams were using slightly wider tires, and pumping the tires to pressures determined by their procedures for the weight of the rider and bike, and road conditions. Poertner referried to chip seal and gravel as rough. Poertner says he is impressed by Chung, Anhalt and others who have worked with mathematical formulas and gather data with specific tools. Poertner accepts testing on rollers and rotating drums.

This kind of testing involves some machinery. When testing became feasible enough for riders to tinker and test, it also became more feasible for manufacturers and industry stakeholders to test. Testing on machines can be standardized and scaled – and is less costly for manufacturers:

It is relatively straightforward to measure rolling resistance under controlled conditions. A large rotating drum or a set of rollers can be used to reproducibly identify relatively minor differences in rolling resistance allowing different brands, models and sizes to be compared and ranked to identify the “fastest” tyres. The influence of other variables — including tyre pressure, different inner tube materials, and for tubular tyres, the method of gluing — has also been tested.

….

It was Tom Anhalt that first raised the possibility that there was more to rolling resistance than friction alone. By comparing his “lab” data with real-world data, Anhalt noticed an unexpected increase in rolling resistance when high tyre pressures were used on the road. Jan Heine and Josh Poertner subsequently confirmed these observations, ushering in a fresh view on rolling resistance and renewed appreciation for lower tyre pressures.

CyclingTips, May 2017, “What is the optimal tyre pressure?“

Poertner says he thinks roll-down testing is very limited. He appears to view Frank Berto’s work as out of date. Poertner is focussed on the marginal gains of improving aerodynamic performance. Poertner’s views are influencing cycling influeners – e.g. Lennard Zinn:

… if there is a question about whether a fatter tire is faster than a skinnier one on a rough road, where the bigger tire should have the advantage, then on a smooth road, the narrower tire will likely come out ahead. And even if there is little or no difference in rolling resistance, the advantage will go to the narrower tire overall, due to its lighter weight and lower aerodynamic drag. Contrary to that René Herse blog you sent me, bigger tires are slower aerodynamically, except when the rim is wider than the tire.

As for the René Herse tire rolling-resistance results … This is the methodology the author (Jan Heine) employed for those René Herse tire tests. I respect the enormous amount of work, time and effort that went into those tests. On the other hand, you can’t accurately quantify a small friction difference between tires, tire widths, or tire pressures when the main thing you’re actually measuring, namely aerodynamic drag, dwarfs those tiny differences.

…..

I’m still left with the fact that the main thing determining the riders’ speeds was wind resistance, since rolling resistance is so much smaller of an effect. That’s why, if we really wanted to be able to quantify what tire pressure, width, or model was faster than another, we needed to do it in a lab, and it couldn’t be just any lab, as I explain[ed][November 23, 2021, Technical FAQ]

Lennard Zinn, VeloNews, December 14, 2021, “Technical FAQ: Tire Rolling Resistance testing methodology“

“Unfortunately, the only way we can truly know the tire pressure breakpoint for a particular rider on a particular surface is to conduct virtual elevation testing (Chung Method testing), which is a methodology whereby we can use real-world data sets to back-out rider CdA and Crr to very high degrees of accuracy. Having done hundreds of these tests, what we find is that the ‘fastest tire’ in the field is the same one we find on the smooth or rough drum in the lab, but the breakpoint pressure depends greatly on rider size/weight/body composition, as that is what is ultimately driving the whole spring/mass/damper side of the equation.

“If you wanted to test that with a machine, you’d have to do some sort of shake rig testing (as we do with racecars) to determine the spring/mass/damping relationship at each tire contact patch and then model that into your bump drum to simulate that spring/mass/damper on top of the tire. Again, the fastest tire will still be the fastest tire, but you could then accurately predict breakpoint!

“This is what makes our tire pressure calculator so unique; it is a curve fit of thousands of real-world virtual elevation data points taken with pro athletes over a 6+ year period. No, the challenge with this data set is that the selection of tires used is extremely top tier. So, the breakpoint is likely a bit high for those running less extravagant tires, and secondly, our athletes are the fittest in the world, so the breakpoint is likely higher than for the average consumer, as these data were produced with athletes all having very low body fat percentage and therefore, lower hysteresis than most normal people!

….

” … roll-down testing, as you know, is a terrible tool for looking at Crr, and I would go as far as saying that it really just can’t/doesn’t work unless you are trying to parse very good from very bad tires.”

— Josh Poertner, Silca president

” … misinterpretation of smooth drum tests has led to misleading conclusions, and really mostly about pressures. Smooth roller tests on tires of equivalent construction, but varying widths, shows that at equivalent pressures, wider tires test faster on the smooth drums, and, with “appropriate” pressures in each, are basically equivalent. Yes, smooth roller tests, or rough roller tests without damping, don’t properly demonstrate breakpoint pressures. Now that this is understood, it’s also important to remember that below breakpoint pressures, roller testing is a very valuable tool for evaluating tire hysteresis losses.”

— Tom Anhalt

Lennard Zinn, VeloNews, January 4, 2022, “Technical FAQ: Tire Rolling Resistance testing methodology and verification“

Lennard Zinn did not explore or explain Tom Andhalt’s comment on the limitations on drum/roller tests at breakpoint pressure.

Poertner assisted journalists at the Hearst publication Bicycling with an article in the spring 2022 issue (Volume 63, No. 4 at p. 65-66, if one has access to this paywalled magazine. I had access through a public library access licence). A test rider was timed and power output was recorded riding a bike equipped with Pirelli P Zero Race TLR tires in three widths – 26, 28 and 30 mm. Each tire width was at three pressure combinations (F/R psi: 90/95, 70/75, 50/55) over two 2.5 mile courses – a smooth and flat (paved) bike path, and a rolling road with “mostly good quality pavement”. Poertner is cited for explaining Tom Anhalt’s breakpoint math, as saying that wider tires are not necessarily faster, and as a supporting the writer’s interpretation of the test results:

“There is the conventional wisdom that wider tires have lower rolling resistance, and if you took a given tire construction and just scaled it, you would probably find that to be true. But in the real world, because of the way tire makers make their tires, that is not always true. I know this can be hard to hear … but it really just depends.”

….

Its not surprising that a 30 mm tire pumped up to 90/95 was the fastest on … smooth flat road. At [20 mph] rolling resistance is not getting overwhelmed by the aerodynamic penalty of the larger tire.

….

The biggest variable that affects your ideal tire pressure (in terms of speed) will be the surface on which you ride.

Bike and tire manufacturers prefer to test on rollers and drums, and deprecate roll-down tests. there are no standards for the tests or the use of tests in manufacturing and marketing.

In road racing, slightly wider tires and lower pressures have become popular, but the adoption of wider tires in competitive road cycling has been limited. The use of wider tires affects frame design. Bicycle manufacturers are competing to produce lighter and faster bikes. Bike manufacturers are replacing metal with plastic composite. At present, carbon fiber is an expensive single-use plastic. Some bike companies greenwash their use of carbon fiber composite as dematerialization. This uses carbon fuels – the energy costs are significant. The road racing interests have tried to get aerobic gains by reshaping bikes and components and changing cycling apparel.

My Tires

My bike in the last half of 2019, 2020, 2021 and 2022 was a 2019 model Cannondale Topstone with WTB tubeless ready wheels to fit 700c tires on a 23 mm. (inner bead diameter) rim. I ran the wheels and tires as clinchers with normal basic butyl rubber inner tubes. The WTB Nano tires had knobs, shown in the photo below. The main tread shows as dusty grey; the raised knobs are black. The larger 4 sided knobs were about 4 mm. front to back x 5.7 mm. The thin knobs on the center line were 14.4 mm. fron to back x 3.75 mm. across, and spaced 5.1 mm. apart. An image of the tread pattern of knobs, arranged in chevrons pointing in the path of travel, seen from the front, is below. These were fairly small knobs, and pretty typical of the tread pattern of modern tires. They were quiet – nearly silent. WTB marked the range of inflation from minimum 35 psi/2.4 bars/240 K.Pa to maximum 55 psi/3.8 bars/380 K.Pa.

Those tires, at 700c x 40 mm., were slightly too big to allow me to put fenders on that bike.

I replaced the WTB Nanos with 700c x 38 mm Panaracer Gravel King SK tires. The actual diameter of this tire (distance from the widest point between the sidewalls) on the 23 mm. rim was about 41.5 mm. The tires were marked with tubed maximum pressure 75 psi/5.3 bars/ 525 kpa, tubeless max 60 psi/ 4.0 bars/ 400 K.Pa

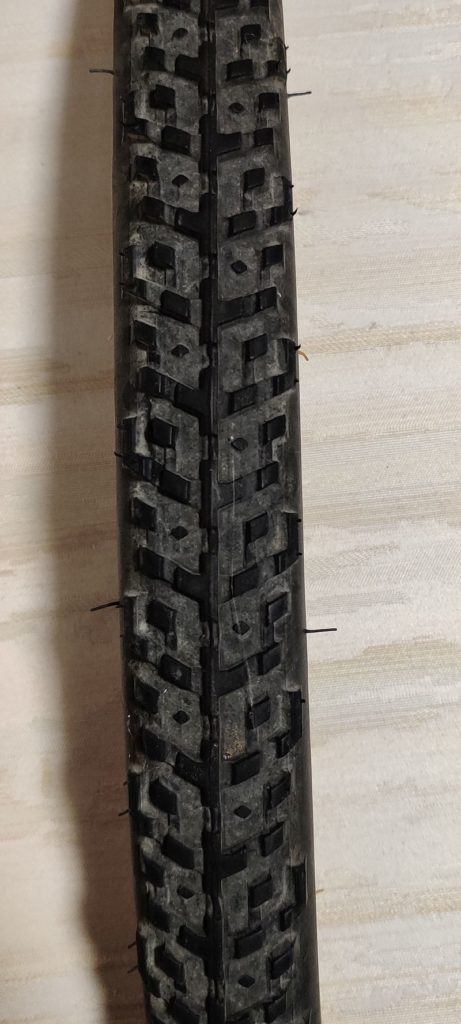

These had, as shown in the image below, 3 rows of 3.5 mm. x. 3.5 mm. square knobs (2.5 or 3 mm high) on the center of the tread, 9 knobs per square centimeters, in a waffle pattern, and some slightly larger knobs on the shoulder between the centre of the tread line and the sidewalls (SK stands for small knob). The small knobs on the center line have the center line thick tread on the contact patch, and some grip on pavement. The knobs were soft enough to give with side pressure.

Tom Anhalt included Panaracer GravelKing (SK) at 32 mm. in his post on gravel tires February 16, 2020.

The Panaracer GravelKing (SK) tires rode smoothly, but seemed to me to squirm on worn asphalt, where bitumen showed on the road surface (Wallace Road, in Central Saanich).

From spring 2021 to May 2022, I rode René Herse Barlow Pass 700c x 38 mm. René Herse has this tire in its “all-road”road line of tires. It is basically a road tire. At 38 mm. itis wider than normal for road bikes. The tread pattern is a faint rib to indicate wear, with a fine file tread on the shoulder. René Herse describes/promotes the tires:

For paved roads and smooth gravel, our all-road tread with its fine ribs is the best choice. It combines excellent performance and grip on pavement with surprising traction on loose surfaces – the supple casing allows the tire to grip the surface much better than a stiffer tire.

René Herse advises that the diameter of its Barlow Pass tires should be within .5 mm of 38 mm. The actual diameter of this tire (distance from the widest point between the sidewalls) on the 23 mm. rim was about 41.5 mm with the Extra Light tire and about 42 mm. with the Endurance tire. The height of the inflated tire was about 710 mm. This is little larger than the manufacturer said I could expect. The maximum pressure specified (tubed) is 75 psi/5.2 bars/515 K.Pa.

I picked up some scattered metal debris, which eventually pushed through the tread and casing and caused a number of small punctures of the tube(s). Some caused rapid deflation. Others caused slow leaks. I may have taken some pinch flats. Supple tires are fragile – as many have said.

I installed René Herse Steilacoom 700c x 38 mm. tires in May 2022. This tire was introduced in 2018. It was the first, and at the time the only René Herse (Compass) knobby tire. Tom Anhalt included this tire in his chart of his test and equations of gravel tires in February 2020. René Herse describes this tire as the ultimate cyclocross tire. It has “dual-purpose knobby tread” which René Herse describes this way:

Our dual-purpose knobbies offer supreme traction on dirt, mud and even snow. They are also a great choice for riders who prefer a more aggressive tread on loose surfaces. On pavement, our knobbies will surprise you with their low rolling resistance and excellent cornering grip. They’re the perfect tire for adventures where you don’t know what lies ahead.

The diameter of the tire (distance from the widest point between the sidewalls) was about 38.5 mm., and the height (inclusive of the knobs) is 710 mm. The maximum pressure specified (tubed) is 75 psi/5.2 bars/515 K.Pa. 38 mm. tires can be run at 40 psi, or less, depending on the weight of rider, bike and gear according to online tire calculators including Silca Velo and René Herse .

The knobs are arranged three rows of overlapping alternating knobs (wider models have 5 rows). The knobs overlapping the center line on the 38 mm. tire are 6.8 mm. x. 6.8 mm. Those knobs are engaged steadily, within the contact patch, when the bike is riding straight. The knobs in the outer rows on the shoulders are 7.7 mm. x 7.7 mm. The larger outer knobs closest to the center row line up with every second gap between the knobs on the center line. Some of the outer knobs seem to be in the contact patch and to bear some load in straight line riding. More of the outer knobs will be engaged when the bike is leaned to turn, or rocked.

René Herse has brought out other wider tires with the same knobs. In 2021-22 René Herse has been promoting the tread design by listing the riders who have used René Herse knobby tires in gravel races and endurance events.

These tires work with my fenders. On my first rides on these tires, I thought the tires lived up to claim that dual purpose knobby tiress were as fast as René Herse’s slick 38 mm. road tires. The hummed a bit. They ran smoothly on fresh asphalt pavement, worn pavement, and packed gravel. The knobby tread does not pick up water from a wet pavement. It does pick up bits of gravel and throw them into my fenders, as other tires do.

Pressure Calculators

Generally

Riders can use online calculators to assist in the determination of optimal pressure. These depend on data sets, and several parameters. The calculators are generally in the cloud – on a commercial site. Some require registration. Few remember a user or previous data. All want the user to state/enter weight, wheel diameter, tire width. Getting the weight of rider + bike + load can involve standing on a scale holding the bike, weighing some gear separately, and adding up the weights.

The calculators depend on the rider’s use of a gauge. A rider needs, of course, a pump. Many tire gauges appear to read the nearest bar and the nearest psi. My gauge can read the nearest psi but only reads the nearest .1 bars. Tire gauges, like hoses, have to connect to tire valves. Some air bleeds off. Gauges are vulnerable to wear and tear, and can deliver inconsistent readings.

Some calculators want the use to classify the riding surface. On any given ride, I may encounter a few hundred meters of new pavement, a lot of worn pavement, some chipseal and some gravel. This parameter cannot even be predicted some days. A rider will live with the pressure in the tires, unless the rider want to deflate or pump tires en route.

Silca Velo

The Silca Pro Tire Pressure Calculator is free – it does not charge a fee for registration or use. It no longer asks me to register or log in, but perhaps has tracked me and identified me. It requires 7 parameters – some are drop-down choices. It asks for weight of rider + bike + load, as other calculators do. It asks me to enter, from drop-down menus:

- wheel diameter;

- tire width to the nearest mm. – actual measured width, not manufacturer’s stated width (this is possible with a caliper);

- “Tire type”;

- average speed. The 6 options start at Recreational and include “Pro Tour”;

- Weight distribution – a front/rear % split:

- Time trial or triathlon 50/50;

- Road 48/52;

- Gravel 47/53;

- Mountain bike 46.5/53.5;

- Surface condition

Surface condition parameter has 10 choices (as of June 2022) from “Track (Indoor wood)” to “Category 4 Gravel”. There is a visual guide. The difference in optimal pressure between smooth pavement and chipseal can be about .4 bars (nearly 6 psi). I use worn pavement or Cat. 1 gravel (not “poor” pavement) as the closest estimatse of local conditions.

This calculator will state calculated optimal pressures to the nearest psi or .05 bar. (1 bar = 14.5 psi. At two decimal places, the bar number also give the pressure in K.Pa; 1 bar = 100 K.Pa). The optimal value for a recreational speed on poor pavement, bad gravel or a dirt trail, is almost a minimum pressure. It is worth checking pressure almost weekly and making time to pump tires up in case they have lost .2 or .3 bars.

René Herse

The René Herse Tire Pressure calculator does not calculatedifferent pressures for front and rear tires. It requires only two parameters: weight and tire width. It provides two optimal settings a “soft” setting and “hard setting”. It is based on Frank Berto’s tests and his theory that tire drop was the best signal or symptom of optimal pressure.

The soft setting is close to the Silca setting for Cat. 1 gravel. The hard setting is close to the Silca setting for tires of the same width, for worn pavement.